Spray drying is a one-step continuous unit operation that employs liquid atomization to produce droplets that are dried to individual particles when moved in a hot gaseous drying medium. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator.

The three stages that occur in a spray dryer before drying is accomplished include:

The nature of the final product obtained after drying in a spray dryer depends on;

Contents

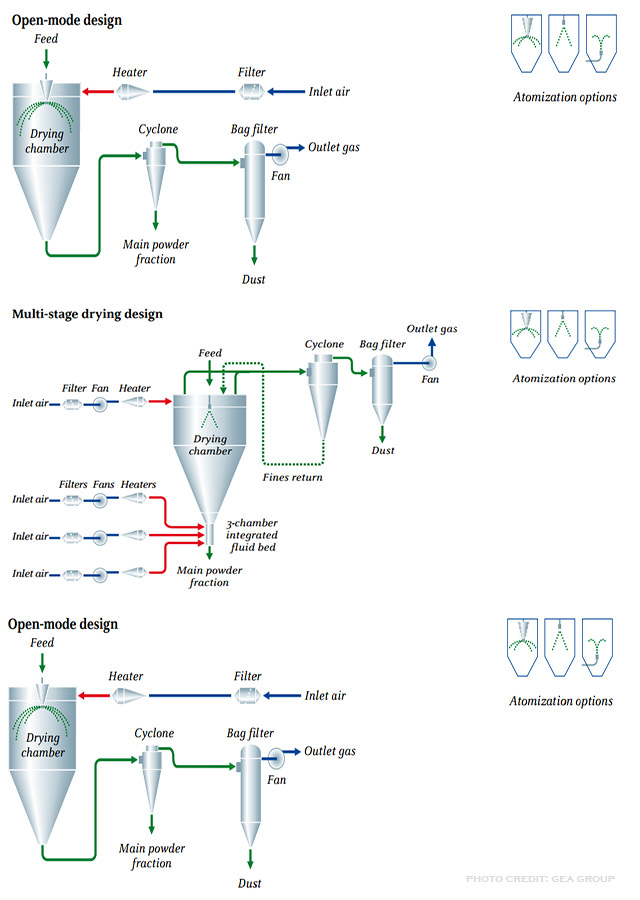

The different process layouts of spray dryer include;

Read Also: Rotary Dryer

1. Spray dryer is used in drying pharmaceuticals like penicillin, blood products, enzymes, vaccines, etc.

2. It is used in the production of excipients and co-processed excipients with increased flowability, compatibility, and tablet disintegration.

3. To improve drug compressibility and reduce capping tendencies in crystals.

4. It is equally used in the preparation of matrix microcapsule containing drug substances and a biodegradable polymer in order to obtain controlled drug release formulation.

5. It is employed in enhancing solubility and dissolution rates of poorly soluble drugs by formation of pharmaceutical complexes or via the development of solid dispersion thus increasing bioavailability.

6. It is used in the production of dry powder formulation/dry powder aerosol and thermoabile materials.

Apart from its applications in the pharmaceutical industries, spray dryers also find use in;

7. Chemical industries e.g. phenol-formaldehyde resin, catalysts, PVC emulsion type, amino acids etc.

8. Ceramic industries e.g. aluminum oxide, carbides, iron oxides, kaolin, etc.

9. Dyestuffs and pigments e.g. chrome yellow, food color, titanium dioxide, paint pigments, etc.

10. Fertilizer production e.g. nitrates, ammonium salts, phosphates, etc.

11. Detergent and surface-active agents e.g. detergent enzymes, bleach powders, emulsifying agents etc.

12. Food industries e.g. milk, whey, egg, soya protein, etc.

13. Fruits and vegetables e.g. banana, tomatoes, coconut milk, etc.

15. Beverage e.g. coffee, tea, etc.

16. Biochemical industries e.g. algae, fodder antibiotics, yeast extracts, enzymes, etc.

17. Environmental pollution control e.g. flue gas desulfurization, black liquor from paper-making etc.

1. Product quality and properties can be effectively controlled and maintained through the entire drying operation.

2. Thermolabile products/ pharmaceuticals can be dried at atmospheric pressure and low temperature.

3. Spray dryer permits high- tonnage production in continuous operation adaptable to conventional PLC control (Programmable Logic Controller) and it is relatively simple to operate.

4. Feedstock in solution, slurry, emulsion, paste, and melt form can be dried if pumpable.

5. Corrosion problem is minimal and the selection of materials of construction of spray dryer is simplified since the dried material comes in contact with the equipment surfaces in an anhydrous condition.

6. Spray dryer produces dry powder particles of controllable particle size, shape, form, moisture content, and other specific properties irrespective of dryer capacity and heat sensitivity.

7. Spray dryer handles a wide range of production rates and provides extensive flexibility in its design that is product specification are readily met through the selection of appropriate spray dryer design and its operation from a wide range of available design.

8. It is an energy-intensive equipment because;

1. Spray dryer is bulky and also expensive to install.

2. It is difficult to clean after use.

3. It has a low thermal efficiency that is a lot of heat is wasted during operation.

4. Solid materials cannot be dried using spray dryers.

5. Product degradation or fire hazard may result from product deposit on the drying chamber.

REFERENCES

Arun S. Mujumdar (2015). Handbook of Industrial Drying. CRC Press, Taylor and Francis Group, New York.

http://m.authorstream.com/presentation/keerthi09-443902-spray-drying-pharmaceutical-industry/

http://www.niro.com/niro/cmsdoc.nsf/webdoc/ndkw5y7gne

http://www.niroinc.com/technologies/spray_drying_tech.asp

Comments6

Very helpful sir, thanks

You are welcome.

Very useful correct information on spray drying.

Thanks

Information is helpful

Thanks